WZL

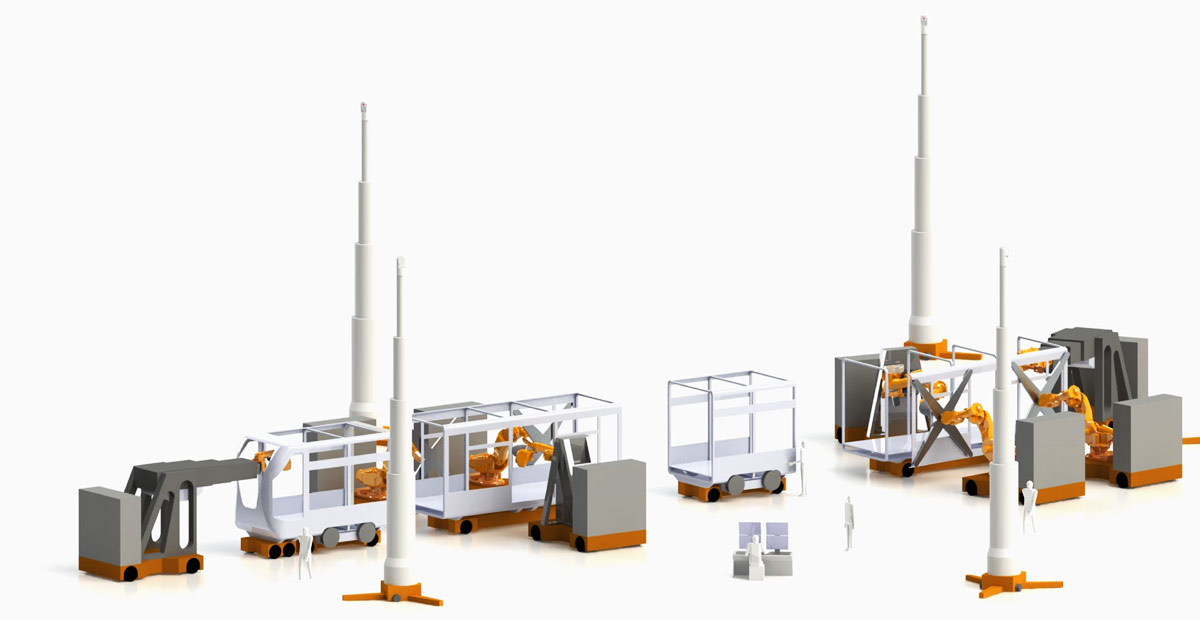

Future assembly is directed towards resilient production of individualized products. All required resources, such as mobile robots, automated guided vehicles and employees move freely around the factory. On-demand, they autonomously reorganize themselves to carry out global objectives and assembly processes in real-time. Assembly processes are no longer realized by rigidly linked lines but along optimal job routes between mobile assembly stations. Networked resources provide all information for the digital twin of the assembly systems. Based on the digital twin, automated production planning and control systems analyzes possible system configurations and provides the goals for autonomous resource agents. Automation of automation ensures that automated resources can be deployed successfully down to lot size one. We call this approach Line-less Assembly Systems (LAS) and Line-less Mobile Assembly Systems (LMAS).

These paradigms are the blueprint for future, resilient and sustainable industrial assembly.

In collaboration with our partners and domain experts, we develop innovative automation solutions, organizational concepts and implement algorithms for the assembly of demanding products from batch size 1 to mass production across all industries.

Considering our RWTH Aachen University network, we combine an entrepreneurial perception of production and scientific expertise in automation, mobile robotics, measurement technology, control engineering as well as artificial intelligence. The holistic perspective on industrial assembly from individual processes to distributed productions sites is an inherent part of our approach.

As a center we provide a joint research, communication and work platform for users, system integrators and manufacturers. Automation technology and customized demonstrator implementation is executed in the Living Lab. This comprehensive infrastructure for rapid prototyping and testing of cutting-edge technologies offers the freedom for conducting scientific experiments in the realm of collaborative research activities.

WZL

WZL

Across the world and for many decades now the Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University has stood for successful and forward-thinking research and innovation in the area of production engineering. In six different work areas, research activities not only relate to fundamental theories and findings but also to the application of findings in an industrial context. Furthermore, practical solutions are worked out for the purposes of rationalizing production.

The Fraunhofer IPT combines knowledge and experience in all fields of production technology. In the areas of process technology, production machines, production metrology and quality as well as technology management, it offers partners and customers tailor-made solutions and immediately actionable results for a connected, adaptive production.